Denor Modular contactors have been market-validated and are recognized as highly reliable electromagnetic contactors. They hold a notable share in the global market. Furthermore, Denor’s contactors have obtained the 3C certification from Mainland China, as well as international certifications including CE, TUV, VDE, and UL. This ensures that our products are compliant for sale in North America, including the United States and Canada.

Throughout various experiments and testing phases, we encountered a plethora of technical terminologies related to contactor technology. We believe it is essential to share these terms with engineers who need to understand and use contactors effectively.

List of Technical Terms for Contactors

Here’s a comprehensive list of important technical terms related to modular contactors that you may find useful:

3.1.1 overcurrent

current exceeding the rated current

[SOURCE: IEC 60050-441:1984, 441-11-06]

3.1.2 short-circuit

accidental or intentional conductive path between two or more conductive parts forcing the electric potential differences between these conductive parts to be equal to or close to zero

[SOURCE: IEC 60050-151:2001, 151-12-04]

3.1.3 short-circuit current

overcurrent resulting from a short circuit due to a fault or an incorrect connection in an electric circuit

[SOURCE: IEC 60050-441:1984, 441-11-07]

3.1.4 overload

operating conditions in an electrically undamaged circuit, which cause an overcurrent [SOURCE: IEC 60050-441:1984, 441-11-08]

3.1.5 overload current

overcurrent occurring in an electrically undamaged circuit

3.1.6 ambient air temperature

temperature, determined under prescribed conditions, of the air surrounding the complete switching device or fuse

Note 1 to entry: For switching devices or fuses installed inside an enclosure, it is the temperature of the air outside the enclosure.

[SOURCE: IEC 60050-441:1984, 441-11-13]

3.1.7 conductive part

part which is capable of conducting current although it may not necessarily be used for carrying service current

[SOURCE: IEC 60050-441:1984, 441-11-09]

3.1.8 exposed conductive part

conductive part which can readily be touched and which is not normally alive, but which may become alive under fault conditions

Note 1 to entry: Typical exposed conductive parts are walls of enclosures, operating handles, etc.

[SOURCE: IEC 60050-441:1984, 441-11-10]

3.1.9 electric shock

physiological effect resulting from an electric current through a human or livestock [SOURCE: IEC 60050-826:2022, 826-12-01]

3.1.10 live part

conductor or conductive part intended to be energized in normal operation, including a neutral conductor, but by convention not a PEN conductor or PEM conductor or PEL conductor

Note 1 to entry: This concept does not necessarily imply a risk of electric shock.

[SOURCE: IEC 60050-826:2022, 826-12-08, modified ─ Rewording of the definition and addition of a Note 1 to entry.]

3.1.11 protective conductor (identification: PE) conductor provided for purposes of safety

EXAMPLE Protection against electric shock.

Note 1 to entry: In an electrical installation, the conductor identified PE is normally also considered as protective earthing conductor.

[SOURCE: IEC 60050-826:2022, 826-13-22, modified ─ Rewording of the definition, addition of a new example and a new Note 1 to entry.]

3.1.12 neutral conductor

conductor electrically connected to the neutral point and capable of contributing to the distribution of electric energy

[SOURCE: IEC 60050-826:2021, 826-14-07]

3.1.13 PEN conductor

conductor combining the functions of both a protective earthing conductor and a neutral conductor

[SOURCE: IEC 60050-826:2022, 826-13-25]

3.1.14 PEM conductor

conductor combining the functions of both a protective earthing conductor and a mid-point conductor

[SOURCE: IEC 60050-826:2022, 826-13-26]

3.1.15 PEL conductor

conductor combining the functions of both a protective earthing conductor and a line conductor [SOURCE: IEC 60050-826:2022, 826-13-27]

3.1.16 enclosure

part providing a specified degree of protection of equipment against certain external influences and a specified degree of protection against approach to or contact with live parts and moving parts

Note 1 to entry: This definition is similar to IEC 60050-441:1984, 441-13-01, which applies to assemblies.

[SOURCE: IEC 60050-441:1984, 441-13-01, modified ─ Rewording of the definition and new Note 1 to entry.]

3.1.17 integral enclosure

enclosure which forms an integral part of the equipment

3.1.18 utilization category

<switching device or fuse> combination of specified requirements related to the condition in which the switching device or the fuse fulfils its purpose, selected to represent a characteristic group of practical applications

Note 1 to entry: The specified requirements can concern e.g. the values of making capacities (if applicable), breaking capacities and other characteristics, the associated circuits and the relevant conditions of use and behaviour.

[SOURCE: IEC 60050-441:1984, 441-17-19]

Switching devices

3.2.1 switching device

device designed to make or break the current in one or more electric circuits

Note 1 to entry: A switching device can perform one or both of these operations.

[SOURCE: IEC 60050-441:1984, 441-14-01, modified ─ Addition of a Note 1 to entry.]

3.2.2 mechanical switching device

switching device designed to close and open one or more electric circuits by means of separable contacts

Note 1 to entry: Any mechanical switching device can be designated according to the medium in which its contacts open and close, e.g. air, SF6, oil.

[SOURCE: IEC 60050-441:1984, 441-14-02]

3.2.3 semiconductor switching device

switching device designed to make and/or break the current in an electric circuit by means of the controlled conductivity of a semiconductor

Note 1 to entry: This definition differs from IEC 60050-441:1984, 441-14-03 since a semiconductor switching device is also designed for breaking the current.

[SOURCE: IEC 60050-441:1984, 441-14-03, modified ─ Addition of “and/or break” and new

Note 1 to entry.]

3.2.4 fuse

device that, by the fusing of one or more of its specially designed and proportioned components, opens the circuit in which it is inserted by breaking the current when this exceeds a given value for a sufficient time

Note 1 to entry: The fuse comprises all the parts that form the complete device

[SOURCE: IEC 60050-441:1984, 441-18-01]

3.2.5 circuit-breaker

mechanical switching device, capable of making, carrying and breaking currents under normal circuit conditions and also making, carrying for a specified time and breaking currents under specified abnormal circuit conditions such as those of short circuit

[SOURCE: IEC 60050-441:1984, 441-14-20, modified ─ “Duration” replaced with “time”.]

3.2.6 mechanical contactor contactor

mechanical switching device having only one position of rest, operated otherwise than by hand, capable of making, carrying and breaking currents under normal circuit conditions including operating overload conditions

Note 1 to entry: The term “operated otherwise than by hand” means that the device is intended to be controlled and kept in working position from one or more external supplies.

Note 2 to entry: A household contactor can have a handle as additional means for operation. In some countries, contactors can be controlled by a signal from the energy supplier during off-peak hours. An end user is allowed to open or close manually the contactor if necessary.

Note 3 to entry: A contactor is usually intended to operate frequently.

[SOURCE: IEC 60050-441:1984, 441-14-33, modified ─ Addition of Notes to entry.]

3.2.7 electromagnetic contactor

contactor, in which the force for closing the normally open main contacts or opening the normally closed main contacts is provided by an electromagnet

Note 1 to entry: The electromagnet can be electronically controlled.

3.2.8 electronically controlled electromagnet

electromagnet in which the coil is controlled by a circuit with active electronic elements

3.2.9 latched contactor

contactor, the moving elements of which are prevented by means of a latching arrangement from returning to the position of rest when the operating means are de-energized

Note 1 to entry: The latching, and the release of the latching, can be mechanical, electromagnetic, pneumatic, etc.

Note 2 to entry: Because of the latching, the latched contactor actually acquires a second position of rest and, according to 3.2.6 is not, strictly speaking, a contactor. However, since the latched contactor in both its utilization and its design is more closely related to contactors in general than to any other classification of switching device, it is considered proper to require that it complies with the specifications for contactors wherever they are appropriate.

[SOURCE: IEC 60050-441:1984, 441-14-34]

3.2.10 semiconductor contactor solid state contactor

device which performs the function of a contactor by utilizing a semiconductor switching device

Note 1 to entry: A semiconductor contactor can also contain mechanical switching devices.

3.2.11 pilot switch

non-manual control switch actuated in response to specified conditions of an actuating quantity

Note 1 to entry: The actuating quantity can be pressure, temperature, velocity, liquid level, elapsed time, etc.

[SOURCE: IEC 60050-441:1984, 441-14-48]

3.2.12 push-button

control switch having an actuator intended to be operated by force exerted by a part of the human body, usually the finger or palm of the hand, and having stored energy (spring) return

[SOURCE: IEC 60050-441:1984, 441-14-53]

3.2.13 short-circuit protective device SCPD

device intended to protect a circuit or parts of a circuit against short-circuit currents by interrupting them

3.2.14 surge arrester

device designed to protect the electrical apparatus from high transient overvoltages and to limit the duration and frequently the amplitude of the follow-on current

[SOURCE: IEC 60050-614:2016, 614-03-51, modified ─ Addition of “to protect the electrical apparatus from high transient overvoltages and”.]

Parts of switching devices

3.3.1 pole

<switching device> portion of a switching device associated exclusively with one electrically separated conducting path of its main circuit and excluding those portions which provide a means for mounting and operating all poles together

Note 1 to entry: A switching device is called single-pole if it has only one pole. If it has more than one pole, it can be called multipole (two-pole, three-pole, etc.) provided the poles are or can be coupled in such a manner as to operate together.

[SOURCE: IEC 60050-441:1984, 441-15-01]

3.3.2 main circuit

<switching device> all the conductive parts of a switching device included in the circuit which it is designed to close or open

[SOURCE: IEC 60050-441:1984, 441-15-02]

3.3.3 control circuit

<switching device> all the conductive parts (other than the main circuit) of a switching device which are included in a circuit used for the closing operation or opening operation, or both, of the device

[SOURCE: IEC 60050-441:1984, 441-15-03]

3.3.4 auxiliary circuit

<switching device> all the conductive parts of a switching device which are intended to be included in a circuit other than the main circuit and the control circuits of the device

Note 1 to entry: Some auxiliary circuits fulfil supplementary functions such as signalling, interlocking, etc., and, as such, they can be part of the control circuit of another switching device.

[SOURCE: IEC 60050-441:1984, 441-15-04]

3.3.5 contact

<mechanical switching device> conductive parts designed to establish circuit continuity when they touch and which, due to their relative motion during an operation, open or close a circuit or, in the case of hinged or sliding contacts, maintain circuit continuity

[SOURCE: IEC 60050-441:1984, 441-15-05]

3.3.6 contact (contact piece)

one of the conductive parts forming a contact [SOURCE: IEC 60050-441:1984, 441-15-06]

3.3.7 main contact

contact included in the main circuit of a mechanical switching device, intended to carry, in the closed position, the current of the main circuit

[SOURCE: IEC 60050-441:1984, 441-15-07]

3.3.8 auxiliary contact

contact included in an auxiliary circuit and mechanically operated by the switching device [SOURCE: IEC 60050-441:1984, 441-15-10]

3.3.9 auxiliary switch

<mechanical switching device> switch containing one or more control and/or auxiliary contacts mechanically operated by a switching device

[SOURCE: IEC 60050-441:1984, 441-15-11]

3.3.10 “a” contact make contact

control or auxiliary contact which is closed when the main contacts of the mechanical switching device are closed and open when they are open

[SOURCE: IEC 60050-441:1984, 441-15-12]

3.3.11 “b” contact break contact

control or auxiliary contact which is open when the main contacts of the mechanical switching device are closed and closed when they are open

[SOURCE: IEC 60050-441:1984, 441-15-13]

3.3.12 release

<mechanical switching device> device, mechanically connected to a mechanical switching device, which releases the holding means and permits the opening or the closing of the switching device

Note 1 to entry: A release can have instantaneous, time-delay, etc. operation.

[SOURCE: IEC 60050-441:1984, 441-15-17]

3.3.13 actuating system

<mechanical switching device> whole of the operating means of a mechanical switching device which transmits the actuating force to the contact pieces

Note 1 to entry: The operating means of an actuating system can be mechanical, electromagnetic, hydraulic, pneumatic, thermal, etc.

3.3.14 actuator

part of the actuating system to which an external actuating force is applied

Note 1 to entry: The actuator can take the form of a handle, knob, push-button, roller, plunger, etc.

[SOURCE: IEC 60050-441:1984, 441-15-22]

3.3.15 position indicating device

part of a mechanical switching device which indicates whether it is in the open, closed, or, where appropriate, earthed position

[SOURCE: IEC 60050-441:1984, 441-15-25]

3.3.16 terminal

conductive part of a device provided for electrical connection to external circuits

3.3.17 screw-type terminal

terminal intended for the connection and disconnection of conductors or for the interconnection of two or more conductors, the connection being made, directly or indirectly, by means of screws or nuts of any kind

3.3.18 screwless-type terminal

terminal intended for the connection and disconnection of conductors or for the interconnection of two or more conductors, the connection being made, directly or indirectly, by means of springs, wedges, eccentrics or cones, etc.

3.3.19 universal terminal

terminal for the connection and disconnection of all types of conductors (solid, stranded and flexible)

[SOURCE: IEC 60998-2-2:2002, 3.101.1, modified – “(rigid and flexible)” replaced with “(solid, stranded and flexible)”.]

3.3.20 non-universal terminal

terminal for the connection and disconnection of a certain kind of conductor only (for example, solid conductors only or solid and stranded conductors only)

[SOURCE: IEC 60998-2-2:2002, 3.101.2, modified – “rigid [solid and stranded]” replaced with “solid and stranded”.]

3.3.21 push-wire terminal

non-universal terminal in which the connection is made by pushing in solid or stranded conductors

[SOURCE: IEC 60998-2-2:2002, 3.101.3, modified – “rigid (solid or stranded)” replaced with “solid or stranded”.]

3.3.22 thread-forming tapping screw

tapping screw having an uninterrupted thread

Note 1 to entry: It is not a function of this thread to remove material from the hole. Note 2 to entry: An example of a thread-forming tapping screw is shown in Figure 1.

3.3.23 thread-cutting tapping screw

tapping screw having an interrupted thread

Note 1 to entry: The thread is intended to remove material from the hole.

Note 2 to entry: An example of a thread-cutting tapping screw is shown in Figure 2.

3.3.24 clamping unit

part of a terminal necessary for the mechanical clamping and the electrical connection of the conductor(s)

3.3.25 unprepared conductor

conductor which has been cut and the insulation of which has been removed for insertion into a terminal

Note 1 to entry: A conductor, the shape of which is arranged for introduction into a terminal or the strands of which are twisted to consolidate the end is considered to be an unprepared conductor.

3.3.26 prepared conductor

a conductor the end of which is fitted with an attachment such as eyelet, sleeve or cable lug [SOURCE: IEC 60050-442:1998, 442-01-27]

3.3.27 solid conductor

conductor consisting of a single wire

Note 1 to entry: The cross-section of the solid conductor can be circular or shaped.

Note 2 to entry: Solid conductor is defined as class 1 conductor in IEC 60228, or by IEC TR 60344, or equivalent AWG/kcmil.

[SOURCE: IEC 60050-461:2008, 461-01-06, modified – In Note 1 to entry, “may” changed to “can”, and Note 2 to entry has been added.]

3.3.28 stranded conductor

conductor consisting of a number of wires, all or some of which are wound in a helix

Note 1 to entry: Stranded conductor is defined as class 2 conductor in IEC 60228, or by IEC TR 60344, or equivalent AWG/kcmil.

[SOURCE: IEC 60050-151:2001, 151-12-36, modified – Note 1 to entry has been added.]

3.3.29 rigid conductor

solid or stranded conductor having wires of such diameters, or so assembled, that the conductor is not suitable for use in a flexible cable.

[SOURCE: IEC 60947-1:2020, 3.5.31]

3.3.30 flexible conductor

stranded conductor having wires of diameters small enough and so assembled that the conductor is suitable for use in a flexible cable

Note 1 to entry: Flexible conductor is defined as class 5 or class 6 conductor in IEC 60228, or by IEC TR 60344, or equivalent AWG/kcmil.

[SOURCE: IEC 60050-461:2008, 461-01-11, modified – Note 1 to entry has been added.]

Operation of switching devices

3.4.1 operation

<mechanical switching device> transfer of the moving contact(s) from one position to an adjacent position

Note 1 to entry: For a circuit-breaker, this can be a closing operation or an opening operation.

Note 2 to entry: If distinction is necessary, an operation in the electrical sense, e.g. make or break, is referred to as a switching operation, and an operation in the mechanical sense, e.g. close or open, is referred to as a mechanical operation.

[SOURCE: IEC 60050-441:1984, 441-16-01]

3.4.2 operating cycle

<mechanical switching device> succession of operations from one position to another and back to the first position through all other positions, if any

[SOURCE: IEC 60050-441:1984, 441-16-02]

3.4.3 operating sequence

<mechanical switching device> succession of specified operations with specified time intervals [SOURCE: IEC 60050-441:1984, 441-16-03]

3.4.4 closing operation

<mechanical switching device> operation by which the device is brought from the open position to the closed position

[SOURCE: IEC 60050-441:1984, 441-16-08]

3.4.5 opening operation

<mechanical switching device> operation by which the device is brought from the closed position to the open position

[SOURCE: IEC 60050-441:1984, 441-16-09]

3.4.6 closed position

<mechanical switching device> position in which the predetermined continuity of the main circuit of the device is secured

[SOURCE: IEC 60050-441:1984, 441-16-22]

3.4.7 open position

<mechanical switching device> position in which the predetermined dielectric withstand voltage requirements are satisfied between open contacts in the main circuit of the device

Note 1 to entry: This definition differs from IEC 60050-441:1984, 441-16-23 to meet the requirements of dielectric properties.

[SOURCE: IEC 60050-441:1984, 441-16-23, modified ─ Replacement of “clearance” with “dielectric withstand voltage requirements are satisfied”.]

3.4.8 position of rest

<contactor> position which the moving elements of the contactor take up when its electromagnet or its compressed-air device is not energized

[SOURCE: IEC 60050-441:1984, 441-16-24]

3.4.9 inching jogging

energizing a motor or solenoid repeatedly for short periods to obtain small movements of the driven mechanism

3.4.10 plugging

stopping or reversing a motor rapidly by reversing the motor primary connections while the motor is running

Characteristic quantities

3.5.1 nominal value

value of a quantity used to designate and identify a component, device, equipment, or system

Note 1 to entry: The nominal value is generally a rounded value.

[SOURCE: IEC 60050-151:2001, 151-16-09]

3.5.2 limiting value

in a specification of a component, device, equipment, or system, the greatest or smallest admissible value of a quantity

[SOURCE: IEC 60050-151:2001, 151-16-10]

3.5.3 rated value

value of a quantity used for specification purposes, established for a specified set of operating conditions of a component, device, equipment, or system

[SOURCE: IEC 60050-151:2001, 151-16-08]

3.5.4 rating

set of rated values and operating conditions [SOURCE: IEC 60050-151:2001, 151-16-11]

3.5.5 prospective current

of a circuit and with respect to a switching device or a fuse> current that would flow in the circuit if each pole of the switching device or the fuse were replaced by a conductor of negligible impedance

Note 1 to entry: The method to be used to evaluate and to express the prospective current is specified in the relevant publications.

[SOURCE: IEC 60050-441:1984, 441-17-01]

3.5.6 prospective peak current

peak value of a prospective current during the transient period following initiation

Note 1 to entry: The definition assumes that the current is made by an ideal switching device, i.e. with instantaneous transition from infinite to zero impedance. For circuits where the current can follow several different paths, e.g. polyphase circuits, it further assumes that the current is made simultaneously in all poles, even if only the current in one pole is considered.

[SOURCE: IEC 60050-441:1984, 441-17-02]

3.5.7 maximum prospective peak current

<AC circuit> prospective peak current when initiation of the current takes place at the instant which leads to the highest possible value

Note 1 to entry: For a multipole device in a polyphase circuit, the maximum prospective peak current refers to a single pole only.

[SOURCE: IEC 60050-441:1984, 441-17-04]

3.5.8 breaking current

<switching device or fuse> current in a pole of a switching device or in a fuse at the instant of initiation of the arc during a breaking process

Note 1 to entry: For AC the current is expressed as the symmetrical RMS value of the AC component.

[SOURCE: IEC 60050-441:1984, 441-17-07, modified ─ Addition of a new Note 1 to entry.]

3.5.9 breaking capacity

<switching device or fuse> value of prospective current that a switching device or a fuse is capable of breaking at a stated voltage under prescribed conditions of use and behaviour

Note 1 to entry: The voltage to be stated and the conditions to be prescribed are dealt with in the relevant product standard.

Note 2 to entry: For AC, the current is expressed as the symmetrical RMS value of the AC component. Note 3 to entry: For short-circuit breaking capacity, see 3.5.11.

[SOURCE: IEC 60050-441:1984, 441-17-08, modified ─ Addition of Notes 2 and 3 to entry.]

3.5.10 making capacity

<switching device> value of prospective making current that a switching device is capable of making at a stated voltage under prescribed conditions of use and behaviour

Note 1 to entry: The voltage to be stated and the conditions to be prescribed are dealt with in the relevant product standard.

Note 2 to entry: For short-circuit making capacity, see 3.5.12.

[SOURCE: IEC 60050-441:1984, 441-17-09, modified ─ Addition of a new Note 2 to entry.]

3.5.11 short-circuit breaking capacity

breaking capacity for which the prescribed conditions include a short-circuit at the terminals of the switching device

[SOURCE: IEC 60050-441:1984, 441-17-11]

3.5.12 short-circuit making capacity

making capacity for which prescribed conditions include a short circuit at the terminals of the switching device

[SOURCE: IEC 60050-441:1984, 441-17-10]

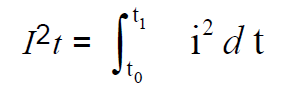

3.5.13 joule integral

I2t

integral of the square of the current over a given time interval

[SOURCE: IEC 60050-441:1984, 441-18-23, modified ─ Deletion of Notes to entry.]

3.5.14 cut-off current (let-through current)

maximum instantaneous value of current attained during the breaking operation of a switching device or a fuse

Note 1 to entry: This concept is of particular importance when the switching device or the fuse operates in such a manner that the prospective peak current of the circuit is not reached.

3.5.15 applied voltage

<switching device> voltage which exists across the terminals of a pole of a switching device just before the making of the current

Note 1 to entry: This definition applies to a single-pole device. For a multipole device. it is the phase-to-phase voltage across the supply terminals of the device.

[SOURCE: IEC 60050-441:1984, 441-17-24, modified ─ New Note 1 to entry.]

3.5.16 recovery voltage

voltage which appears across the terminals of a pole of a switching device or a fuse after the breaking of the current

Note 1 to entry: This voltage can be considered in two successive intervals of time, one during which a transient voltage exists, followed by a second one during which the power frequency voltage or the steady-state recovery voltage alone exists.

Note 2 to entry: This definition applies to a single-pole device. For a multipole device it is the phase-to-phase voltage across the supply terminals of the device.

[SOURCE: IEC 60050-441:1984, 441-17-25, modified ─ New Note 2 to entry.]

3.5.17 transient recovery voltage TRV

recovery voltage during the time in which it has a significant transient character

Note 1 to entry: The transient voltage can be oscillatory or non-oscillatory or a combination of these depending on the characteristics of the circuit, the switching device or the fuse. It includes the voltage shift of the neutral of a polyphase circuit.

[SOURCE: IEC 60050-441:1984, 441-17-26, modified ─ Replacement in the note of “and the switching device” with the “switching device or the fuse”.]

3.5.18 power-frequency recovery voltage

recovery voltage after the transient voltage phenomena have subsided [SOURCE: IEC 60050-441:1984, 441-17-27]

3.5.19 DC steady-state recovery voltage

recovery voltage in a DC circuit after the transient voltage phenomena have subsided, expressed by the mean value where ripple is present

[SOURCE: IEC 60050-441:1984, 441-17-28]

3.5.20 clearance

distance between two conductive parts along a string stretched the shortest way between these conductive parts

3.5.21 creepage distance

shortest distance along the surface of an insulating material between two conductive parts

Note 1 to entry: A joint between two pieces of insulating material is considered part of the surface.

3.5.22

working voltage

highest RMS value of the AC voltage or the highest value of the DC voltage which can occur (locally) across any insulation at rated supply voltage, transients being disregarded, in open circuit conditions or under normal operating conditions

3.5.23 impulse withstand voltage

highest peak value of an impulse voltage, of prescribed form and polarity, which does not cause breakdown under specified conditions of test

3.5.24 power-frequency withstand voltage

RMS value of a power-frequency sinusoidal voltage which does not cause breakdown under specified conditions of test

3.5.25 pollution

any addition of foreign matter, solid, liquid or gaseous (ionized gases) that can affect dielectric strength or surface resistivity

3.5.26 pollution degree

<environmental conditions> conventional number based on the amount of conductive or hygroscopic dust, ionized gas or salt and on the relative humidity and its frequency of occurrence, resulting in hygroscopic absorption or condensation of moisture leading to reduction in dielectric strength and/or surface resistivity

Note 1 to entry: The pollution degree of the micro-environment to which equipment is exposed can be different from that of the macro-environment where the equipment is located because of protection offered by means such as an enclosure or internal heating to prevent absorption or condensation of moisture.

Note 2 to entry: For the purposes of this document, the pollution degree is that of the micro-environment.

3.5.27 micro-environment

<clearance or creepage distance> ambient conditions which surround the clearance or creepage distance under consideration

Note 1 to entry: The micro-environment of the creepage distance or clearance and not the environment of the equipment determines the effect on the insulation. The micro-environment can be better or worse than the environment of the equipment. It includes all factors influencing the insulation such as climatic and electromagnetic conditions, generation of pollution, etc.

3.5.28 overvoltage category

<in a circuit or within an electrical system> conventional number based on limiting (or controlling) the values of prospective transient overvoltages occurring in a circuit (or within an electrical system having different nominal voltages) and depending on the means employed to influence the overvoltages

Note 1 to entry: In an electrical system, the transition from one overvoltage category to one of a lower category is obtained through appropriate means complying with interface requirements, such as an overvoltage protective device or a series-shunt impedance arrangement capable of dissipating, absorbing, or diverting the energy in the associated surge current, to lower the transient overvoltage value to that of the desired lower overvoltage category.

3.5.29 co-ordination of insulation

correlation of insulating characteristics of electrical equipment with the expected overvoltages and the characteristics of overvoltage protective devices on the one hand, and with the expected micro-environment and the pollution protective means on the other hand

3.5.30 homogeneous field uniform field

electric field which has an essentially constant voltage gradient between electrodes, such as that between two spheres where the radius of each sphere is greater than the distance between them

3.5.31 inhomogeneous field non-uniform field

electric field which does not have an essentially constant voltage gradient between electrodes

3.5.32 tracking

progressive formation of conducting paths which are produced on the surface of a solid insulating material, due to the combined effects of electric stress and electrolytic contamination on that surface

3.5.33 comparative tracking index CTI

numerical value of the maximum voltage in volts at which a material withstands 50 drops of a test solution without tracking

Note 1 to entry: The value of each test voltage and the CTI are divisible by 25. Note 2 to entry: This definition is based on 3.5 of IEC 60112:2020.